Gas grid connection installed for the first hydrogen customer at the Bad Lauchstädt energy park

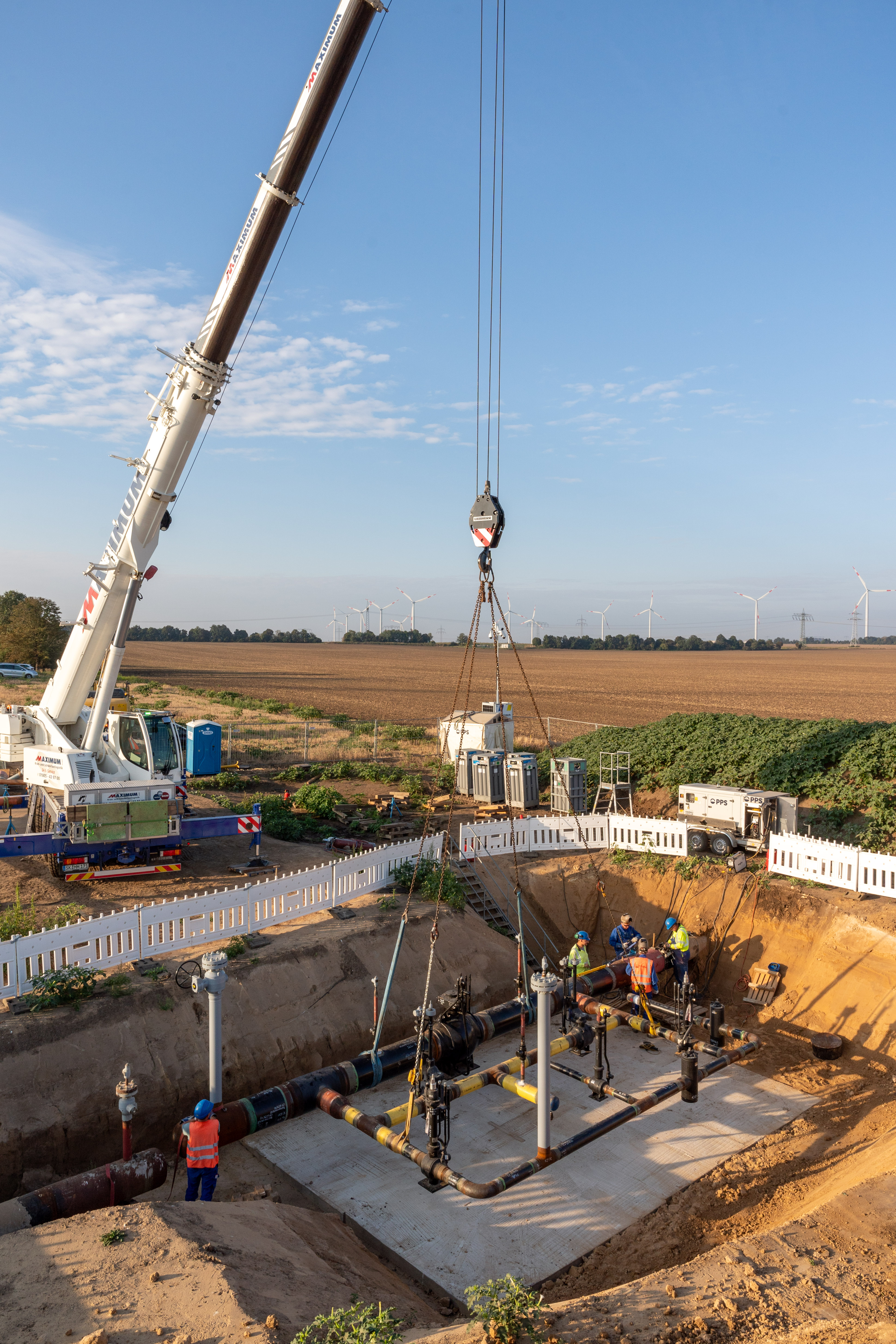

- ONTRAS lifts branch valve assembly into place at gas grid connection point

- Infrastructure along the green hydrogen value chain is thus seamlessly completed

On behalf of ONTRAS Gastransport GmbH (ONTRAS), a new branch valve assembly was lifted into place today for the Bad Lauchstädt energy park project on the future long-distance gas pipeline FGL 701. The new junction will enable ONTRAS to ensure the uninterrupted and secure supply of green hydrogen to TotalEnergies Raffinerie Mitteldeutschland GmbH (“TRM”). “We have passed an important milestone with the installation of the new branch valve assembly connecting our first hydrogen customer to the Bad Lauchstädt Energy Park. We are thus creating the conditions for a continuous supply of green hydrogen to the TRM refinery and taking another important step by connecting a first customer to the future hydrogen core network,” says Cornelia Müller-Pagel, project manager in the consortium and Head of Green Gases at VNG AG. The green hydrogen to be transported in the pipeline is produced 25 kilometres away in the electrolysis plant currently being built by Uniper and VNG Handel & Vertrieb GmbH. The electrolysis process uses green electricity generated by the eight wind turbines belonging to the Bad Lauchstädt Energy Park located north of Bad Lauchstädt.

The individual components of the branch valve unit are assembled on site before being lifted into place. This is followed by weld seam and pressure tests and then official acceptance by an expert. The valve assembly, which weighs around 6 tonnes, is then lifted into the pit using a special crane and welded to the existing pipeline. In the subsequent phases, before final connection of the refinery, horizontal bores for the pipes will be drilled under the road in front of the TRM site and a measurement and control station will be installed. Commercial operations are scheduled to start in the 4th quarter of 2025.

With the pipeline FGL 701 and the FGL701.01 branch pipeline, ONTRAS will initially connect the refinery to the electrolysis plant and, in future, to the cavern storage facility in Bad Lauchstädt, which VNG Gasspeicher GmbH, another consortium member, is currently preparing for the large-scale storage of green hydrogen. In future, ONTRAS also plans to connect the Leipzig region to the hydrogen core network via this pipeline and to other new and converted pipelines as part of the IPCEI Green Octopus Central Germany (GO!) project and thus supply the region with sustainably produced hydrogen.

ABOUT THE PROJECT

The Bad Lauchstädt Energy Park is a production-scale real-life laboratory for the production of green hydrogen and its storage, transport, marketing and use. This real-life laboratory is designed to test the entire value chain of green hydrogen on an industrial scale for the first time. A large 30 MW electrolysis plant operated by Sunfire uses renewable electricity from the nearby wind farm to produce green hydrogen. Temporarily stored in a salt cavern specially created for this purpose, the green hydrogen can be fed into the hydrogen supply network for the chemical industry in Central Germany via a converted gas pipeline and used for future urban mobility solutions. The real-life laboratory contributes to research into tomorrow’s green hydrogen technologies, helping to bring them to market maturity – for a technologically strong and future-oriented hydrogen-based economy in the Central Germany region and successful intersectoral energy integration throughout the Federal Republic. To this end, the project partners are investing a total of EUR 210 million, which includes EUR 34 million of funding as a “real-world laboratory for the energy transition” project from the 7th Energy Research Programme of the Federal Ministry of Economics and Climate Protection (BMWK).

Contact:

Katharina Wilsdorf

E-Mail: presse@energiepark-bad-lauchstaedt.de

Telefon: +49 341 2310-9033

Press pictures